15 April 2022

New look for Co-cast brake rotors

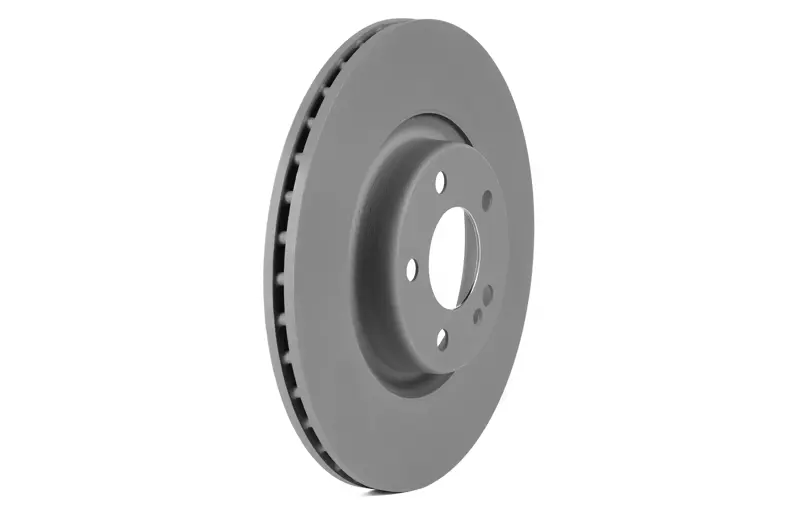

The new treatment gives the range a unique appearance

In 2018, Brembo offered the exclusive range of composite rotors with co-cast technology for the first time in the Aftermarket. The Co-cast rotor is used on all the latest-generation Mercedes premium models, for which Brembo is already the Original Equipment Manufacturer, and it stands out for the use of a steel hub which is co cast to the high carbon cast iron braking surface.

This technology not only ensures superior performance for the braking system but it also reduces the weight of the rotor itself by up to 15%. The Co-cast brake rotor is fully interchangeable with an Original Equipment brake rotor, has passed the strictest bench tests and is approved to ECE-R90 standards.

Now four years on since it was launched, Brembo has decided to revamp the look of its Co-cast range, standardising it with that of the other exclusive Brembo ranges derived from OE production: the range of floating rotors, Dual-cast rotors and the latest new entry, the Lightweight rotors.

The new galvanisation treatment not only ensures the same superior protection levels as UV paint but also lends the co-cast range a unique appearance compared to UV painted integral brake rotors.

The new coating, which is similar to that applied to original equipment brake rotors, is already available on all the Co-cast part numbers in the range.

| BREMBO PART NUMBER | D x TH (MM) |

|---|---|

| 08.D530.13 | 300 x 12 |

| 09.D524.13 | 360 x 36 |

| 09.D525.13 | 295 x 24 |

| 09.D526.13 | 305 x 28 |

| 09.D527.13 | 318 x 30 |

| 09.D527.23 | 318 x 30 |

| 09.D528.13 | 330 x 32 |

| 09.D529.13 | 342 x 32 |

| 09.D529.23 | 342 x 32 |

| 09.D531.13 | 320 x 24 |

| 09.D532.13 | 360 x 26 |

| 09.D533.13 | 300 x 22 |