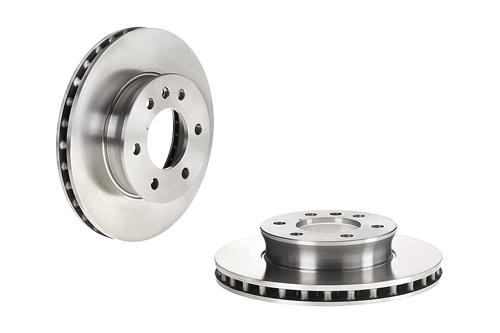

Prime Line

The original product quality

Brake rotors with over 98% vehicle coverage

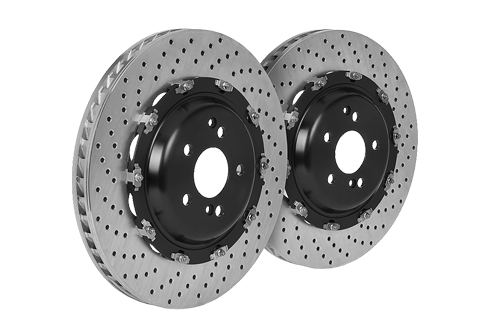

UV paint

Corrosion-resistant and eco-friendly

Low environmental impact and excellent quality allow the UV-coated brake rotor range to establish an alternative benchmark to the original product. The unique metal finish ensures an eye-catching impact.

Standard paint | UV paint | |

|---|---|---|

| Corrosion resistance | Verniciatura Standard icon Average | Verniciatura UV icon High |

| Emissions | Verniciatura Standard icon Contains up to 15% of volatile organic compounds (VOCs) | Verniciatura UV icon Absence of volatile organic compounds (VOCs) |

| Health | Verniciatura Standard icon Contains toxic substances, including methanol. | Verniciatura UV icon Components not hazardous to health. |

| High resistance | Verniciatura Standard icon High resistance to oils and brake fluid. Limited chemical resistance, e.g. to rim cleaners. | Verniciatura UV icon High resistance to chemicals. |

| Energy consumption | Verniciatura Standard icon 4.67 kWh/disc | Verniciatura UV icon 0.08 kWh/disc |

The original product quality.

Appearance

Metallised effect conferring a shiny, clean look to the rotor.

Wide range

More than 600 part numbers, covering the majority of the vehicles on European roads.

Corrosion, humidity and temperature resistance

The resistance is superior to any other products on the market. Rust- resistance is proven by tests in a salt spray chamber.

Eco-friendliness

The water-based UV varnish requires no solvents. The ultraviolet (UV) coating process is extremely energy-efficient.

Intelligent marking

The position of the marking allows mechanics to read of the minimum thickness for replacement easily.

Ready to use

Ready for installation and practical to assemble

Braking surface protective coating

The protective varnish coating, also present on the braking surface, outer diameter and hub, ensures complete protection of the disc.

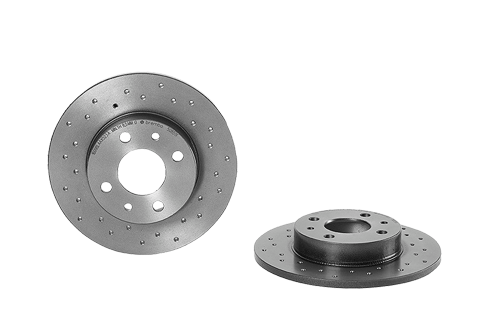

High Carbon

High damping coefficient

The perfect result of Brembo's concept of offering aftermarket products developed with the same parameters as the original equipment, High Carbon (HC) discs ensure comfort and low noise as the result of their high damping coefficient. This results from Brembo technology and the complete control of production in the company’s foundries allowing the variation of the chemical composition of cast iron by increasing the percentage of carbon in High Carbon (HC) discs. High Carbon (HC) discs are used for more than 1000 part numbers for cars and trucks.

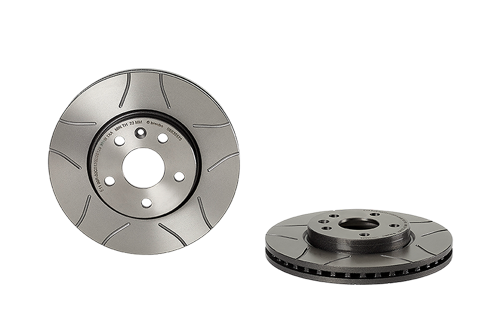

PVT ventilation

Better cooling and resistance to thermal cracking.

The Brembo patent for PVT ventilated brake discs improves the current design by using pillars instead of vanes in the ventilation chamber. The system improves the heat dissipation capacity and increases resistance to thermal cracks by more than 40%. The most notable innovations are increased resistance to cracks, greater heat exchange surface area and greater air turbulence.

PVT Plus:

Performance, durability, efficiency

The cross shape of the ventilation pillars provides greater resistance to thermal cracking, increasing braking performance while offering significant weight reduction. In order to ensure optimal heat exchange, the new PVT PLUS ventilation system also features different geometries for each specific type of disc.