Instructions for replacing the brake caliper

Please read and follow all instructions carefully. You’ll find the same instructions in the brake caliper pack. Remember to keep them for the entire product life cycle. Hand them over to the new owner if you sell your vehicle.

We recommend you only perform those steps required for replacing the spare part or parts desired.

All the information in this article applies to both types of calipers, unless otherwise specified.- Caliper with pad retaining pins

- Caliper with central pin.

- Caliper with central bridge.

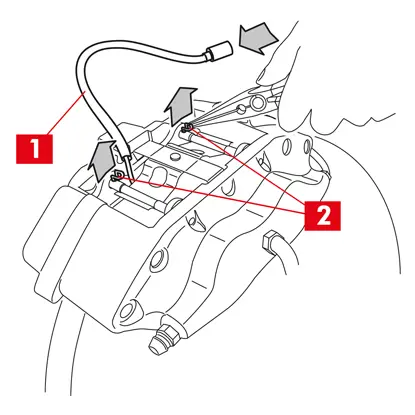

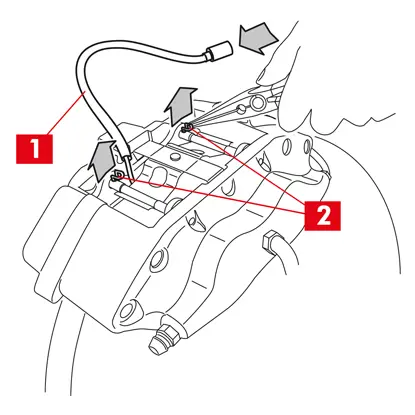

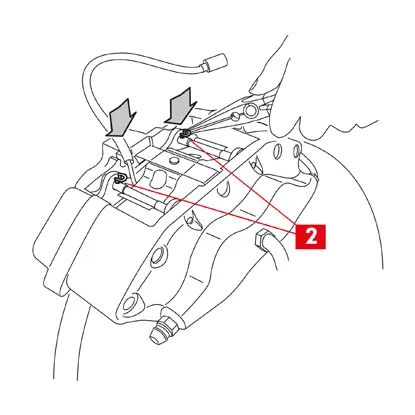

- For models fitted with safety split pins (point 2), remove them using a pair of pliers.

- Slide out one of the pins (point 3) using a hammer and pin driver, far enough to allow the operation to be completed by hand, then remove completely, keeping the spring (point 4) in position with one hand.

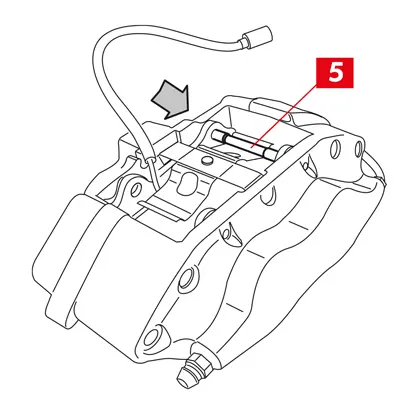

- Remove the spring (point 4) and any other pins (point 5).

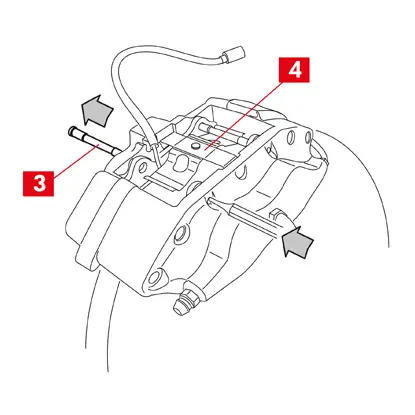

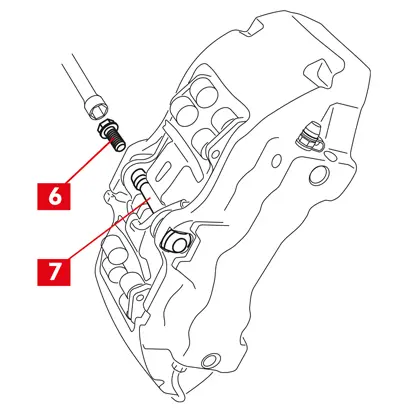

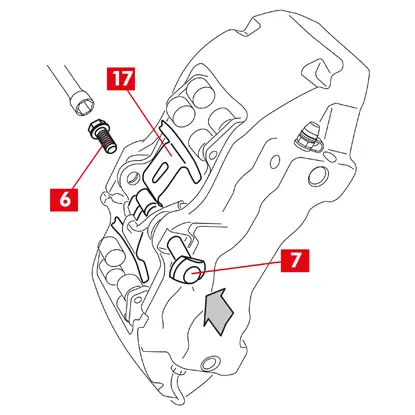

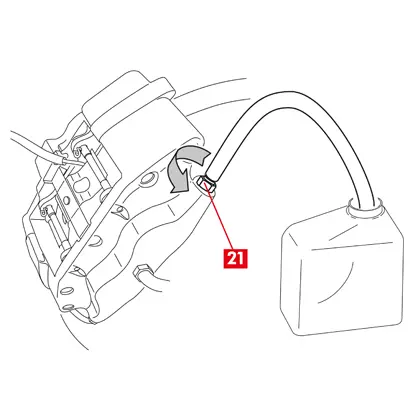

- Note the position of the pin and fastening screw on the caliper to ensure correct re-assembly.

- Using a pipe wrench, unscrew the fastening screw (point 6) of the pin (point 7).

- Remove the fastening screw (point 6).

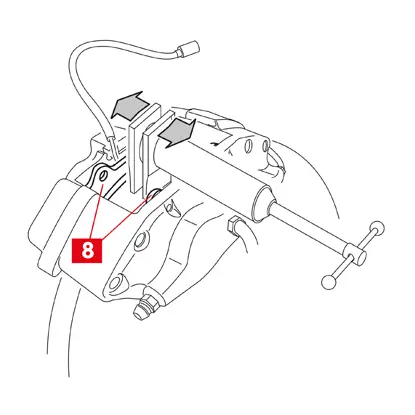

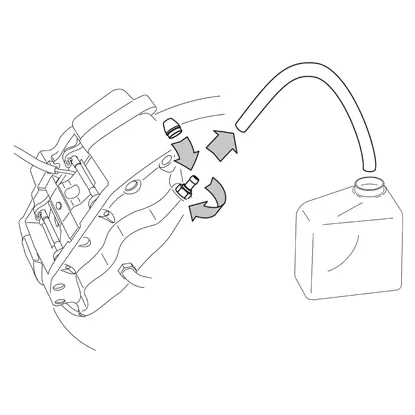

- Slide out the pin (point 7) using a hammer and pin driver, far enough to allow the operation to be completed by hand, then remove completely, keeping the spring in position with one hand. Remove the spring.

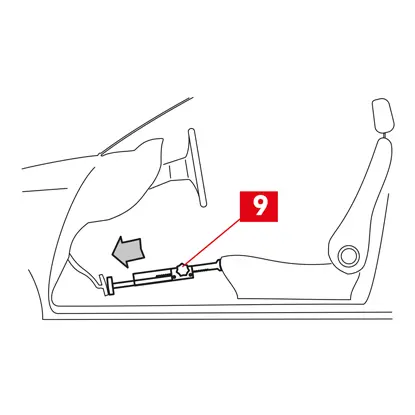

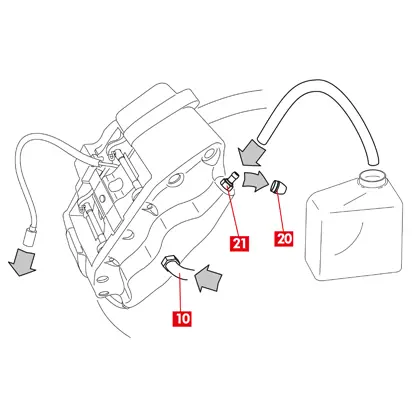

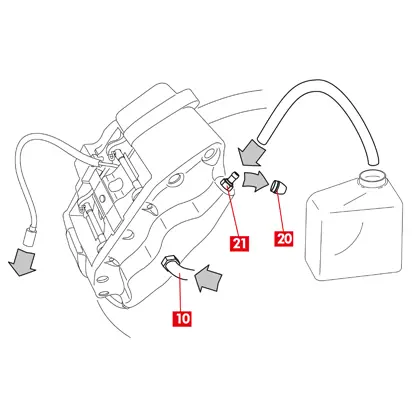

WARNING! This allows the brake hydraulic circuit to be closed, avoiding any brake fluid from leaking.

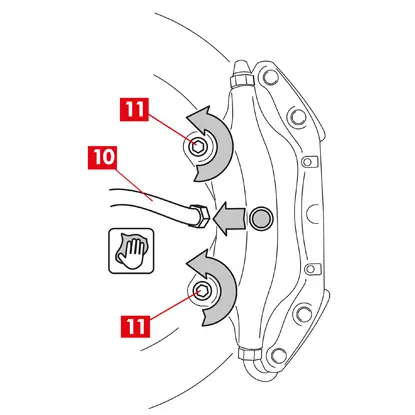

CAUTION! During all the phases described below, make sure the brake fluid does not come into contact with parts of the vehicle which would be damaged, especially painted parts. Promptly wipe off any accidental brake fluid splashes or leaks with kitchen towel and clean with water.

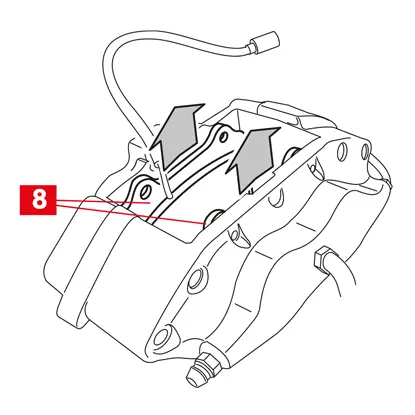

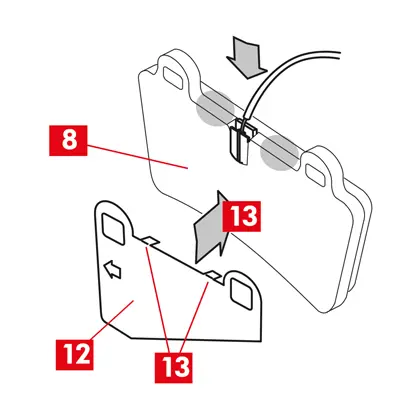

The shims are correctly positioned when the two lips (point 13) rest firmly on the upper edge of the back of the pads and the arrows stamped on them are pointing in the disc rotation direction.

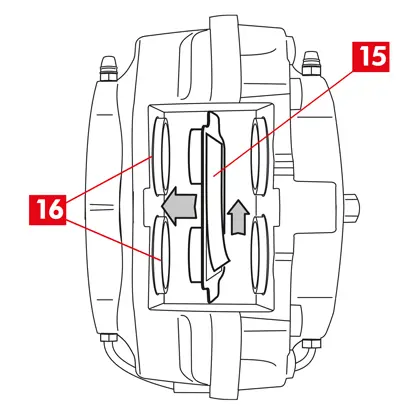

WARNING! Check the correct positioning of any springs in the pad seats.

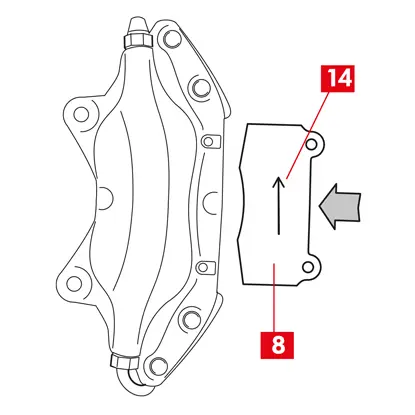

DANGER! Pads must be inserted with the friction material facing the disc.

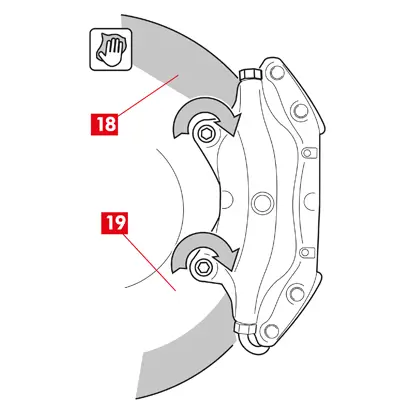

- Refit one of the pins (point 5) in the dedicated seats in the caliper and in the pads, locating it using a hammer and pin driver. A pin is correctly located when it will go no farther and the hammer blow sounds stronger and metallic.

- Refit the spring (point 4) observing the direction of any arrows.

- Refit any other points (point 3) exerting a firm pressure on the spring with one hand, then locate it using a hammer and pin driver.

- Check the spring is correctly positioned.

- For models fitted with safety split pins (point 2), reposition them using a pair of pliers.

- Position the spring (point 17).

- Insert the pin (point 7) in the dedicated seats in the caliper, exerting a firm pressure on the spring with one hand, then locate it using a hammer and pin driver.

- Using a pipe wrench, screw in the fastening screw (point 6) without tightening it completely.

| Bleeder plug | M8x1,25 |

| Tightening torque | 27÷33 Nm |

| Type of screw | M12x1,25 M12x1,5 M12x1,75 M14x1,5 |

| Tightening torque | 100 Nm 115 Nm 115 Nm 165 Nm |

| Bleeder plug | M6x1 M8x1,25 M10x1 M12x1 |

| Tightening torque | 5÷7 Nm 7÷10 Nm 17÷20 Nm 18÷22 Nm |

DANGER! If fluid is leaking from the caliper, repeat all the steps set out in this document to pinpoint the cause and remedy the problem.

Such modification or improper use will void the Limited Warranty, and may subject the individual so using the Product to liability for bodily injury or property damage to others.

In these instructions, the “DANGER!” warning means procedures which, if not observed, have a high degree of probability that they will cause serious injury or even death. “CAUTION”” means procedures which, if not observed, could result in physical damage whereas “WARNING!” means procedures which, if not observed, could possibly cause damage to the vehicle.

DANGER!

Before commencing replacement, ascertain that the spare parts are suitable for the make and model of the vehicle. This Product is vital to the safe operation of the vehicle on which it is installed, and it is intended to be installed only by a skilled, qualified individual who has been trained and/or is experienced in the installation and use for which the Product is intended.

The installer must be equipped with the proper tools of his trade, and with the knowledge and experience to deal with vehicle repairs. Improper or incorrect installation, whether caused by a failure to follow these Instructions faithfully and completely or otherwise, will void the Limited Warranty and could subject the installer to liability in the event of personal injury or property damage.

The worn parts replaced by this Product must not be installed on any other product. This could result in property damage and personal injury, including death.

Avoid contact of grease and other lubricants with the braking surfaces of the disc and pads as this could affect the efficiency of the braking system.

Always check that the brake fluid level in the reservoir is between the minimum and maximum levels indicated on the reservoir. An incorrect level can cause brake fluid leaks or reduced braking system efficiency. Too much or too little brake fluid in the reservoir could cause the brakes not to perform properly resulting in personal injury, including death.

Brembo shall not be liable for any damage or injury caused to or by any person operating a vehicle on which a replacement product has been improperly installed.

CAUTION!

Replaced parts must be disposed of in accordance with the law.

It is vital to avoid sharply striking and/or damaging the Product, its parts and its components, as this can impair their efficiency and may cause them to malfunction. If necessary, replace any damaged part or component. To avoid injury we recommend the following:

- Use suitable equipment to prevent the inhalation of dust raised during cleaning of the parts.

- Always wear gloves during disassembly and assembly of components with sharp edges.

- Do not allow skin surface to make direct contact with the friction material of pads and brake shoes since this could cause abrasions.

- Do not introduce your hands in the seat of the pads when removing the caliper pistons using compressed air as this involves the risk of crushing your hands.

- Avoid direct contact with the brake fluid as it can cause irritation to the skin and eyes. In the event of accidental contact, clean thoroughly in accordance with the vehicle or brake fluid manufacturer’s instructions.

- Do not subject the electrical components to electrostatic charges or to impact which could damage the plastic parts.

- Protect the disassembled electrical components from humidity.

- Ensure correct connection of any electrical contacts, checking that the warning lights come on. If they do not, non-operation of the warning lights can cause a reduction in efficiency of the braking system, or brake signalling failure.

WARNING!

This warranty constitutes the only warranty provided in relation to this product and replaces any other warranties, both verbal and written.

Is there anything else you want to ask?