The brakes of the future: The braking system of the future

Part 2. The braking system on the cars of tomorrow

Now that we have analysed the transformations which cars have undergone during their evolution in part one of "The brakes of the future”, we will attempt to understand what the braking system of the future will look like, in the light of certain current trends, such as the environmental sustainability variable and the introduction of autonomous driving.

Environmental sustainability and the braking system: what does the future hold?

Let’s begin with the environmental sustainability variable, in particular with the toughest challenge, the reduction of carbon dioxide emissions. To reduce the amount of CO2 released into the atmosphere, we need to reduce consumption. In addition to depending on the type of engine used, consumption levels hugely depend on the weight of the vehicle, which is the reason why the braking system needs to be amended in order to reduce the weight.

How to reduce the weight of the braking system

The technologies we will take into account here to reduce the weight of the car’s braking system are the brake rotors, brake pads and calipers.

Brake rotor technologies

Let’s start with the brake rotors, by analysing the principal technologies, some of which are already on the market, and others that will become available in the immediate future:

- composite rotors in cast iron and aluminium (BMW)

cast iron braking surface and aluminium hub, mechanically joined with steel pins: this solution reduces weight by about 15% compared with an integral cast iron brake rotor.

- composite rotors in cast iron and steel (MB)

since 2014, Mercedes offers its high-end models with a brake rotor featuring a cast iron braking surface, interference-fitted to a steel hub. The solution, which is produced by Brembo as Mercedes original equipment, reduces weight by about 15%.

- co-cast rotors in cast iron and steel (MB aftermarket)

this solution by Brembo joins a cast iron braking surface to a steel hub by co-casting the two materials, which reduces the weight by 15% while retaining performance and styling intact.

- eco-cast rotors in cast iron and aluminium

this is a solution by Brembo which has not been marketed yet, and it involves a composite rotor (cast iron for the braking surface and aluminium for the hub) joined via co-casting.

- dual-cast rotors in cast iron and aluminium (first and second generation)

suitable for racing and for sports models, the first generation rotors consist of two parts, carbon cast iron braking surface and aluminium hub, joined by co-casting, with a weight reduction of about 20% and greater system elasticity, to reduce the risk of deformation between the braking surface and the hub.

The second generation rotors utilises a different position of the pins connecting the braking surface to the hub, which improves rotor ventilation and increases the heat dissipation capacity and resistance to thermal cracking.

The second generation rotors utilises a different position of the pins connecting the braking surface to the hub, which improves rotor ventilation and increases the heat dissipation capacity and resistance to thermal cracking.

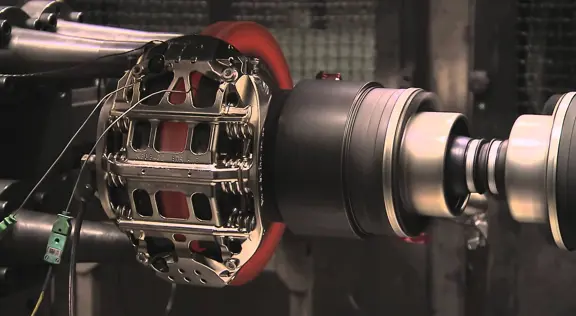

- floating rotors with mechanical connection

high-carbon cast iron rotors connected to an aluminium hub by utilising elastic bushes which guarantee good system elasticity, preventing deformations and unwanted vibrations.

- composite rotors in steel and stainless steel

rotors with a steel hub, mechanically connected to a stainless steel braking surface. By using steel, the thickness of both the braking surface (max 8 mm) and of the hub (2.5 mm) can both be reduced. The braking surface can comfortably withstand temperatures of up to 600°. The weight reduction is approximately 30% compared to cast iron rotors, however the durability of both the rotors and the pads increases. The sheet steel hub is made by deep drawing, in contrast to the holes and slots manufactured by perforating. The braking surface is produced by cold-punching stainless steel. The two components are then assembled, and the resting surface undergoes a final grinding process to meet the tolerance values required.

- integral aluminium rotors

These pose some difficulties due to the critical characteristics that the material exhibits at temperatures above 400° and the use of special brake pads is anticipated. Using aluminium makes it possible to reduce the weight by around 40% compared with a similar cast iron rotor.

- carbon ceramic rotors

Floating rotors which makes use of carbon ceramic material for the braking surface, with a weight reduction of up to 50% compared to cast iron rotors. This technology also offers other advantages: the absence of thermal deformation, a high and constant friction coefficient and superior durability (of over 200,000 km).

Graph 1 - Brake rotor weight reduction

Graph 1 sums up the solutions implemented over the years to reduce the weight of the rotor, which we have listed above. Since their initial use on supercars and sports cars, these solutions have also gradually been implemented on everyday cars, which constitute a more significant portion of the market, and this trend is quite likely to continue in the near future.

Brake pad technologies: Project Lybra

The Lybra project involves the use of a fibreglass shim for the brake pads, instead of the normal metal shim. This shim is therefore moulded together with the friction material in a production process that differs considerably from the one currently used for producing brake pads, with the following advantages:

- brake pad weight reduced by around 30%

- reduced heat conductivity

- corrosion problems eradicated.

This solution is particularly suited to use on the rear axles of electric cars, where regenerative braking results in decreasing use of the rotor, lower operating temperatures and lesser wear.

Caliper technologies: semi-solid metal-forming

Semi-solid metal-forming is a process that makes it possible to produce aluminium brake calipers from secondary aluminium (originating from recycled aluminium) instead of primary aluminium (pure aluminium, originating from the mining of bauxite and alloyed with another material to produce brake calipers), with two main purposes:

- environmentally-friendly, with a smaller environmental impact, thanks to the use of recycled aluminium

- improved mechanical characteristics and lighter calipers thanks to reduced thickness with identical mechanical strength.

Brembo technology expects the use of secondary aluminium, which is melted at 650°C instead of the 740° used in conventional processes. At this melting temperature, the aluminium obtained is in the semi-solid state, avoiding the formation of impurities: the mixed semi-solid structure is arranged in the mould in a spherical or globular structure, which increases the mechanical strength of the caliper. Brembo is currently working on using this same technology for aluminium as well, with the aim of reducing the caliper weight by approximately 8%.

How to reduce the particulate produced by brake pads

The copper and other metals which are deposited on the roads due to brake pad wear prove toxic to certain aquatic micro-organisms. Therefore, in 2010 both the states of California and Washington passed legislation that brake pads sold or fitted in both states must have lower levels of copper and other heavy metals. These "Better Brake Rules" are local rules which could have global repercussions: in both States, 3 different categories of hazardous metal contents are predicted, and from 2025 only level N brake pads can be sold, with a percentage copper of less than 0.5% of the total weight of the friction material.

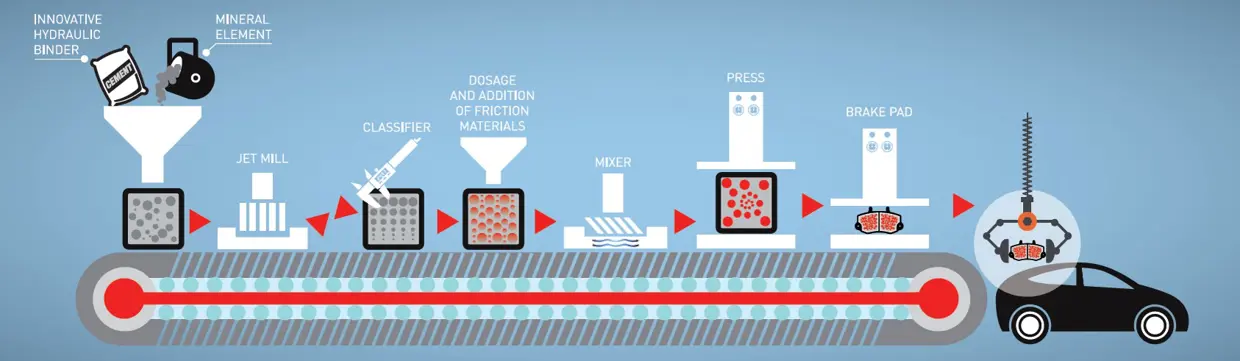

Project Cobra

Brembo, in partnership with the Mario Negri institute, Italcementi and Connecting Ambition, is taking part in Project Cobra, to reduce brake particulate, using a new brake pad production technology that replaces traditional phenolic resins with a new cement-based material.

Phenolic resins are made of phenols and formaldehyde: this is a very volatile and therefore very hazardous substance, as it can find its way into the human respiratory tract.

The new cement-based materials must deliver equivalent performance to traditional materials. This means they meet the high performance standards expected of the most demanding sports applications, while minimising their fine particulate emissions and environmental impact. The new process not only reduces fine particulate during braking, but it also makes it possible to reduce energy during the production process, as well as water consumption. The compound has already been approved to ECE-R90.

Electrification and autonomous driving

As well as reduced emissions and particulate, one very important recent trend concerning the future of the car - and hence of brakes - is electrification and autonomous driving.

SENSIFY™

Is there anything else you want to ask?

Contact the Brembo technical support team. Our technicians will get back to you as soon as possible!