Spare parts: the 10 factors indicating the difference between Original Equipment and Matching Quality

Among the many questions that more and more people are asking Brembo, one of the thorniest issues concerns spare braking components. In fact, with the exception of tyres, everything that is regularly replaced on a vehicle - from the engine oil to the brake pads, coolant and filters – is difficult to assess since it is not visible to the naked eye.

One of the most long-standing issues concerns the dichotomy between Original Equipment (OE) and Matching Quality (standard component) concerning the brakes, but also the glazing, the electrics and even the exhaust system. The terms themselves are quite irksome, and one frequent way to explain the difference is to compare these with generic and original medication.

This is however completely incorrect, because the difference between Original Equipment and Matching Quality is quite notable, not just in terms of brand reputation or advertising investments, as we will explain below. First of all, here is a clarification which should help you get a clear picture of who Brembo is.

As manufacturer of original equipment braking systems and components for multiple car (and motorbike) models for the biggest Makes, thanks to the production plants located across Europe, North and South America and China, Brembo has been an Original Equipment Manufacturer in its own right for over three decades.

Below are 10 differences between Original Equipment and Matching Quality. Before we delve deeply into the differences between the two, here is a useful suggestion to identify Original Equipment products immediately and easily.

Below are 10 differences between Original Equipment and Matching Quality. Before we delve deeply into the differences between the two, here is a useful suggestion to identify Original Equipment products immediately and easily.

How to recognise an Original Equipment product

All Original Equipment products are immediately recognisable because they feature the OE supplier logo on the pack.

For the same reason, recognising OE products from the Brembo Aftermarket range is straightforward. Indeed, the OE supplier logo is present on Brembo boxes of brake pads, rotors, remanufactured calipers, brake shoes and drums.

1. It’s easy to say cast iron

Historically, brake rotors have always been made in cast iron, and to this day the majority of cars on the road uses this material, aside from exclusive supercars that use carbon ceramic materials instead. Many people are unaware however that the term cast iron includes several types of variants which differ in their chemical composition, and hence their performance.

Brembo uses more than 40 different variants of cast iron, in fact. The choice of Original Equipment components in fact exactly mirrors the original equipment material. The same correspondence is not guaranteed by standard components.

2. The huge world of the brake pad

The range of Brembo brake pads guarantees maximum braking safety, thanks to the absolute control of all phases of the production process: from research and development to testing, including the friction compound production and the mechanical machining.

For its brake pads, Brembo uses more than 100 different compounds, designed to offer the most suitable solution for each type of car and driving style, in terms of both performance and comfort. Imagining such a variety for a Matching Quality manufacturer is simply utopia.

3. Appearances can be deceptive

At first glance, a brake rotor with economy quality may appear similar to an Original Equipment product, but who can guarantee that the two will still be aesthetically indistinguishable a few months down the line? There is no guarantee that the effect of a coat of paint will last once it is fitted on a car.

Brembo brake rotors with UV paint treatment guarantee superior corrosion resistance, as confirmed by both salt mist spray tests as well as moisture resistance tests. This not only makes for an attractive product for the car user, but it also translates to greater protection for the brake rotor itself against corrosion and atmospheric agents.

4. Safety lies in numbers

Brembo works closely with car manufacturers during the concept of new models, starting with the prototyping phase, in order to approve the most effective braking system. The study of braking components, including static and road tests, is optimised for the car model they will be equipping.

Indeed, this particular partnership allows Brembo to find out and therefore replicate the narrow tolerance values envisaged for original equipment braking components, which vary from one system to the next. The same cannot be said for standard component manufacturers, where common drawbacks include brake thickness variations (DTV) and rotor oscillation during revolution, and hence run-out.

5. The secret lies on the inside

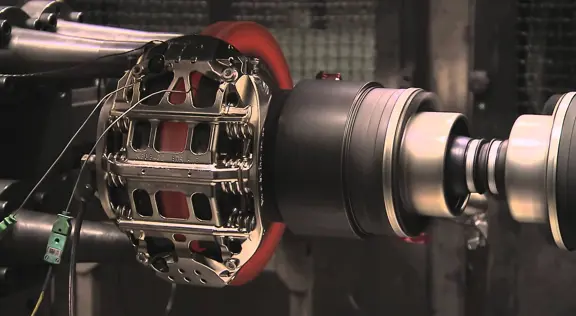

Once upon a time, all you needed to do was to take a look at the surface and finish to identify a good brake rotor. Modern brake rotors are much more complex than one might think, thanks to the ventilation chambers inside, to dissipate the heat as quickly as possible, and which cannot be seen unless to cut the rotor open.

Several Original Equipment rotors are distinguished by pillar ventilation (PVT) patented by Brembo. This technology, owing to the shape and distribution of the pillars, creates air circulation inside the ventilation chamber, which allows for greater heat removal, as well as generating a barrier against the formation of cracks On Brembo’s latest-generation brake rotors, the pillars have a different geometry and are arranged along three rings along the braking surface. Since they are not entitled to, Matching Quality manufacturers cannot use PVT ventilation.

6. The outside also stands out

Brembo brake pads undergo a surface thermal treatment, referred to as scorching, which guarantees maximum efficiency even at the highest temperatures.

Usually not present on economy quality brake pads, scorching is designed to eliminate any gases in advance, which could cause a significant reduction in the friction coefficient between the brake rotor and pad at high temperatures. This means there is no fading, and the braking behaviour is constant.

7. Silence, braking in progress

In addition to guaranteeing optimum braking, Brembo Original Equipment brake pads ensure superior levels of comfort during braking. They achieve this thanks to the multiple layers making up the shim, in other words the sequence of rubber, steel and rubber that dampens. However, the fundamental choice, in this case just as for the performance, concerns the compound, which not only ensures safe braking but also has to guarantee maximum comfort and the absence of tiresome noises and squealing.

There is no need to point out that very few Matching Quality brake pad manufacturers make investments in research and development in this field.

8. Big Brother sees all

A Brembo braking component is only placed on the market if it passes the most stringent tests, which are conducted in all conditions of use, including the most extreme. Starting with static bench tests, during which it undergoes higher load cycles than physically applicable to the vehicle in various environmental conditions.

Next, dynamic bench tests are conducted, to replicate the dynamics of the vehicle the component will be equipping. In this case too, loads above the operating loads are applied to ascertain strength, efficiency, comfort and functionality. Last but not least come the road tests. Seldom do economy component manufacturers have the resources, methodologies and machinery to do all this.

9. Easy assembly

The packaging used for Brembo brake pads provides useful information and technical product data, in addition to the symbols for the international certifications required by various markets.

Installation is also made easy by an extensive range of accessories and assembly kits, included in the box, but also available for downloading from the website. This help is indispensable for directional brake pads, since fitting them on the wrong side increases noise and wear and reduces braking performance.

Installation is also made easy by an extensive range of accessories and assembly kits, included in the box, but also available for downloading from the website. This help is indispensable for directional brake pads, since fitting them on the wrong side increases noise and wear and reduces braking performance.

10. Long live sustainability

Brembo’s commitment to sustainability and to the environment embraces all the brand’s activities, from the initial research and development phases, in order to make increasingly sustainable products, solutions and processes. This approach is also evident in the various standard component manufacturing processes.

The paint used by Brembo entails drying using UV lamps. Since the UV paints are water-based, they differ from traditional paints made with chemical solvents. Energy consumption levels are therefore lower and no Volatile Organic Compounds are emitted.

Is there anything else you want to ask?

Contact the Brembo technical support team. Our technicians will get back to you as soon as possible!